What Are Shrink Sleeves Used For?

Shrink sleeves, also known as tamper-evident bands or neck bands, are a revolutionary packaging solution that evolved into a ubiquitous and versatile tool for product branding and labelling. Shrink bands originated in the mid-20th century, and initially found application in the beverage industry(shrink bands for bottles are still very popular), gaining popularity due to their ability to conform to irregularly shaped containers and provide a 360-degree canvas for vibrant graphics and information. Over the years, technological advancements have propelled shrink sleeves beyond their early limitations, making them an indispensable choice across diverse sectors. Shrink sleeves can now commonly be seen in the pharmaceutical, food and cosmetic industries as a tamper-evident measure for ensuring the safety and integrity of products stored inside.

Heat shrink sleeves offer numerous benefits, contributing to their wide adoption across multiple sectors. These shrink sleeves, typically made from PVC, PETG, or OPS materials, are designed to encase and shrink tightly around a product when heat is applied. This results in a snug fit, enhancing the visual appeal of the packaging and offering a tamper-evident seal, which is used as a branding and marketing tool. This enables companies to enhance the visual appeal of their products through customized designs, logos, and essential product information. The heat shrink bands also provide tamper-evident protection, assuring consumers of the product's safety and preventing any alteration or contamination of the contents inside. Furthermore, shrink wrap bands are practical and cost-effective, as they can be easily applied with heat tunnels or handheld heat guns, eliminating the need for additional packaging materials. From enhancing shelf presence to facilitating product recognition, shrink sleeve has become integral to modern packaging strategies, demonstrating their adaptability across various industries and product categories.

Types Of Shrink Sleeves

Shrink sleeves are widely used in the packaging industry as they provide an effective way to label products and create a visually appealing packaging solution. There are several types of shrink sleeves, namely neck shrink bands, heat shrink sleeves, and combo shrink sleeves. Each type offers unique characteristics and advantages that cater to different packaging needs.

1. Neck Shrink Bands: Neck shrink bands represent a specialized type of shrink sleeve designed primarily for creating a tamper-evident seal on product packaging. These sleeves are tailored to fit around the neck of containers, ensuring the integrity of the product by securely sealing the opening. They are typically used for products like beverages, pharmaceuticals, and food. Neck shrink bands are also often used for customer satisfaction as neck bands provide a clear visual indication of whether a product has been tampered with, instilling confidence in consumers and meeting regulatory requirements. These shrink sleeves also offer an excellent solution for products that require additional brand reinforcement or information, as they provide more space on the neck area than traditional labels.

2. Full Body Shrink Sleeves For Decoration: Full-body shrink sleeves envelop the entire packaging surface, offering a wide surface area around the product for companies to print vibrant graphics and detailed information. Full-body shrink sleeves utilize the application of heat, allowing them to conform tightly to the shape of the container. Shrink bands for bottles is an excellent example for this type of sleeve as it is known for its form-fitting nature, enhancing the overall visual appeal of the product. Widely employed for decorative purposes, these heat shrink bands are a popular choice in industries ranging from cosmetics to beverages. The seamless coverage ensures a visually appealing and cohesive presentation, allowing brands to communicate their message effectively. Full-body shrink sleeves also help brands to stand out in today's competitive market. Moreover, the full-body shrink sleeves provide additional protection against environmental factors, contributing to the longevity of the product's visual appeal on the shelf.

3. Combo Shrink Sleeves: Combo shrink sleeves combine the functionalities of neck shrink bands and full-body shrink sleeves, offering a versatile solution for packaging needs. They typically consist of a neckband on the container's neck and a heat shrink sleeve covering the body of the product, providing a tamper-evident seal while also allowing for ample space for branding and information. This hybrid approach caters to products where both security and aesthetic appeal are crucial. Combo shrink bands find application in various industries, from personal care products to foods, striking a balance between functionality and design.

Shrink Sleeves Usage

Shrink sleeves can be used for a number of different reasons. Below, we will have a look at the most common types of shrink bands and what they are used for.

1. Standard Heat Shrink Band: The standard heat shrink band is a versatile packaging solution, typically made of high-density polyethene or polyolefin. A tamper-evident seal can be easily created by applying these transparent shrink bands around the lid. These kinds of shrink sleeves provide a snug fit and are most commonly used to seal glass jars, aluminum bottles and containers with regular shapes. Its simplicity and effectiveness make it a standard choice in packaging across diverse industries, offering both a protective seal and a branding opportunity.

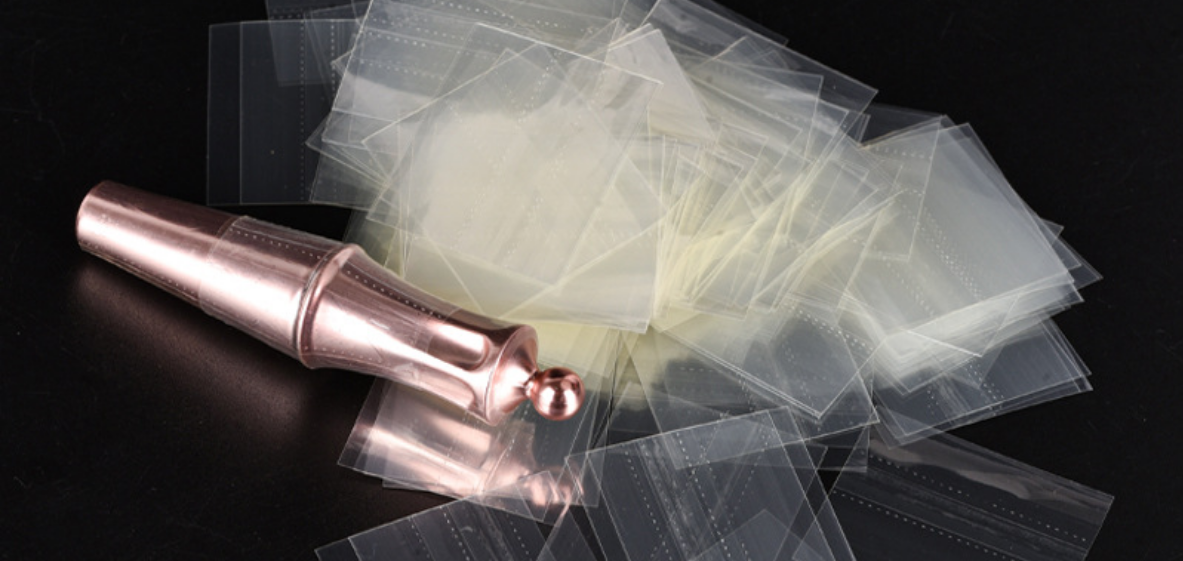

2. Clear Shrink Band: The concept of a clear shrink band or shrink sleeve is intricately linked to packaging and security in the modern consumer market. Designed to provide tamper-evident protection, a clear shrink sleeve is a transparent material that is heat-sealed around the top of a product's container, serving as both a deterrent to potential tampering and a visible indicator of the package's integrity. Ideal for showcasing the contents while ensuring product integrity, the clear shrink bands are widely used in industries where transparency and visual appeal are paramount. The clear shrink band's functionality and purpose are critical components of a well-rounded packaging strategy, enabling businesses to mitigate risks and augment consumer confidence in their products.

3. Custom Made Shrink Sleeve: The Custom made shrink sleeve is a tailored packaging solution that meets unique branding and security requirements. Precision-engineered to fit specific container dimensions, these shrink wrap bands are customized to enhance product aesthetics and functionality. Custom-made shrink bands allow companies to give their plain glass or plastic bottles and jars a unique and budget-friendly makeover that adds a new attraction to their product. Businesses can communicate their identity effectively by combining a tamper-evident seal with branding opportunities. The custom-made shrink bands offer a personalized touch, whether accommodating irregularly shaped containers or incorporating specialized messaging. It is a favored choice for diverse industries seeking a tailored packaging solution that balances security and brand representation with precision and individuality.

Benefits Of Shrink Sleeves

As stated earlier, shrink sleeves have emerged as a revolutionary solution in the packaging industry, offering many advantages to both customers and businesses while also benefiting the environment.

1. Advantages For Customers: From a customer perspective, shrink-sleeve packaging offers significant benefits, enhancing their overall product experience. Firstly, it enhances the visual appeal of products, allowing for vibrant and eye-catching designs that attract attention on store shelves. Heat shrink sleeve also provide 360-degree coverage, ensuring complete product visibility and showcasing important information, such as product details, ingredients, and usage instructions. Furthermore, shrink bands are tamper-resistant, assuring customers of the product's integrity and safety. The durability and resistance to wear and tear contribute to an extended shelf life, maintaining the product's visual appeal over time. This satisfies customers' aesthetic preferences and assures them of the product's authenticity and quality.

2. Advantages For Businesses: For businesses, shrink sleeves represent a powerful tool in brand differentiation and market competitiveness. To begin with, shrink sleeves or shrink wrap bands allow for greater flexibility in packaging design and customization for various shapes and sizes, which helps streamline the packaging process. The ample surface area for branding enables companies to communicate their message effectively, fostering brand recognition and customer loyalty. As a result, businesses can respond swiftly to market trends, ensuring customer satisfaction and maintaining a competitive edge. Heat shrink sleeve is also cost-effective, eliminating the need for pre-labelled containers and allowing businesses to adapt to changing market demands swiftly. The tamper-evident feature enhances product safety, protecting both consumers and the brand's reputation. These advantages contribute to an overall improved customer experience, promoting brand loyalty and repeat purchases.

3. Advantages For The Environment: Notably, shrink sleeves also contribute positively to the environment. Their lightweight nature reduces overall packaging material consumption, minimizing waste generation. Traditional packaging methods often involve the excessive use of materials, leading to waste and pollution. In contrast, heat shrink bands require fewer materials, minimizing environmental impact. Applying shrink sleeves directly to containers eliminates the need for secondary packaging, further reducing environmental impact. The sleeves can be produced using recyclable materials, which reduces the carbon footprint. Additionally, the application process of shrink bands often involves heat, eliminating the need for harmful adhesives or solvents. As businesses increasingly adopt sustainable packaging practices, shrink sleeves align with these eco-conscious initiatives, offering a balance between effective branding and environmental responsibility.

What Materials Are Used To Make Shrink Sleeves

Traditionally, shrink sleeves were made from petroleum-based materials that could take years to decompose and, therefore, had a negative environmental impact. However, with the growing concern for sustainable packaging solutions, the use of bio-plastics and sugarcane-based materials has gained attention. Bio-plastic shrink sleeves and heat shrink bands are made from renewable resources and offer a more eco-friendly alternative without compromising functionality or aesthetics.

One of the primary materials used to make bio-plastic shrink sleeves is derived from sugar cane. This bio-resin is extracted from the stalks of sugar cane plants and can be processed into a versatile packaging material. Shrink wrap bands made from bioplastic and sugarcane materials represent a significant stride towards sustainable and eco-friendly packaging solutions. Bioplastic, derived from renewable resources such as cornstarch or sugarcane, is a plant-based alternative to traditional petroleum-based plastics. This material reduces dependency on fossil fuels and diminishes the carbon footprint associated with packaging production. Shrink sleeves crafted from bioplastic exhibit similar qualities to conventional materials but with the added benefit of being biodegradable and compostable, contributing to a reduction in environmental impact.

To conclude the blog, the evolution of shrink sleeves from their inception in the mid-20th century to their current diverse applications highlights their pivotal role in modern packaging strategies. From neck shrink bands ensuring tamper-evident seals to full-body shrink sleeves providing a massive canvas for branding, the versatility of heat shrink sleeve is evident. The benefits extend beyond aesthetics, offering consumers an exceptional product experience and businesses a competitive edge. Moreover, the shift towards sustainable materials like bio-plastics and sugarcane aligns with global efforts for eco-conscious packaging. Heat shrink bands and shrink sleeves, with their adaptability, security features, and environmental considerations, stand as an embodiment of innovation, catering to the dynamic needs of both industry and the consumer.