The Difference Between Tin Cans and Aluminum Cans

The word 'Tin Can' in today's world is used to sum up all sorts of small metal tins into one category. Most of these modern tin containers are crafted out of aluminum, however, originally this was not the case. Although it is common for people to refer to tin cans and aluminum cans as the same item, these two types of tins are actually quite different from one another.

Tin cans and aluminum cans are used for the same purpose and you will mostly find them being used in the food and cosmetic industries. The main difference lies, however, in the material that they are crafted out off as well as the benefits these materials have to offer. They furthermore have different properties and, most importantly, different manufacturing costs. Aluminum tins are, for example, much stronger yet lighter in weight. On top of that, they are also cheaper to produce and recycle.

Below, we will briefly take you through the main differences between tin cans and aluminum cans. We’ll have a look at what these metal tins are used for, what they are made out off, and what their main properties are.

What Are Metal Tins Used For?

Small metal cans are used for numerous storage purposes. Ever since the year 1810, when the tin can was patented, these metal tins have served us in storing and containing goods. When the tin can was first patented, the small metal container was (as its name suggests) made out of tin. The reason why tin was chosen lies in the fact that this metal is durable and furthermore highly resistant to corrosion. Thanks to this, tin containers can serve perfectly for storing foods and beverages as well as other items such as cosmetics, medicine, and candles.

Starting from the 1960’s, tin can manufacturers gradually started to change from using tin to aluminum. Both aluminum and tin containers are used for the same purposes and for the end-user, it makes little difference from what material your tin is made off. Both type of cans are probably most known for storing and preserving food. The reason behind this lays in the fact that both types of metal are able to protect its content from light and air. They are furthermore durable, corrosion resistant, and recyclable. Nevertheless, these tins do bring along some significant difference for the manufacturers who are actually producing these metal tins.

What Are The Differences Between Tin Cans and Aluminum Cans?

Metal tins were traditionally made out of tin, but nowadays aluminum has become the metal of choice. Both metals generally feature the same properties. There are, however, still some small but important differences. These differences are not that visible for the end-user, but they are of major importance to the manufacturers of these small metal containers.

Properties of Tin:

The element tin is what we consider to be a low-melting crystalline. This sort of metal is malleable at room temperature making it easy to work with. The metal itself is extracted from cassiterite. This is a compound that exists out of tin and oxygen. This compound can be easily refined and processed, making tin an appealing metal to work with for can manufacturers. Another important reason why it is often used for cans is that tin does not corrode easily. Therefore, it allows you to store dry and wet materials alike without the content wearing down the metal food container.

Although tin can be found in many common every-day objects, the metal itself is not as common as it seems. In fact, scientists claim that only 0.0001% of the earth’s crust is made up out of tin – making it one of the rarest ‘’common metals’’ available. Therefore, tin is relatively expensive, costing around $20.61 per KG. (London Metal Exchange, August 2017) Due to this, modern tin cans are actually made from steel that has been finished off with a very thin tin coating. This layer has been applied to prevent the steel from corroding. That’s right; modern tin containers are actually not made from pure tin anymore as this would be unaffordable.

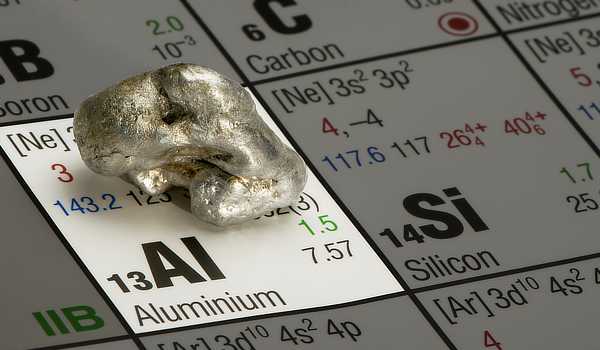

Properties of Aluminum:

Aluminum is, just like tin, a metallic element. The main difference is, however, that aluminum can be more commonly found on our earth. In fact, its presence is abundant – making up around 8.2% of the world’s crust. Aluminum is one of the most commonly found metals on earth, which results in lower prices. As of August 2017, one KG is aluminum costs $2.10 – making it almost 10 times cheaper as tin. (London Metal Exchange, 2017)

Although it is easier to find, aluminum is a bit more difficult to refine due to the fact it is always found in different compounds. Usually, it is found on potassium aluminum sulfate or aluminum oxide. Therefore, different processes need to be applied to refine the aluminum. Although these processes were expensive at first, they have become increasingly more efficient and affordable. The recycling process of aluminum has furthermore developed tremendously over the past decades. As a result, aluminum has become one of the easiest and cheapest metals to recycle. Just like tin, aluminum is resistant against corrosion and easy to work with.

The Main Differences Between Tin and Aluminum

Although tin cans and aluminum cans feature many of the same properties, there are some major differences. The most important differences between tin cans and aluminum cans are:

Tin is heavier than aluminum – making it more difficult and expensive to store and transport. The heavy weight furthermore makes tin cans less sustainable as more CO2 is produced during transportation.

Aluminum is more durable and stronger than tin. This makes it a perfect material for not only the packaging industry but many other industries as well. In fact, aluminum is so durable that it’s even used in the production of airplanes.

Aluminum is a more common material as tin, making it much cheaper.

Aluminum is a bit more difficult to refine, however, easier to work with for manufacturers.

Aluminum is one of the most recycled materials on earth. Recycled aluminum has the same properties as virgin aluminum, but it’s significantly cheaper. Tin, on the other hand, is less efficient for recycling.

The costs saved from recycling aluminum cans are enormous – making it one of the most sustainable packaging materials available today.

Due to the above mentioned reasons, the majority of modern metal tins are crafted out of aluminum. Traditional tin-plated small metal containers are still available, however, less common due to their heavier weight and higher price. When people nowadays refer to tin containers, they usually talk about steel or iron tins that come with a thin tin coating . This type of containers are also known as tin-plated tins.

At uCan-packaging, we offer a wide range of empty tin cans for sale. All our small metal containers are crafted out of high-end and recyclable aluminum. If you’re looking for custom tins, then we’re also happy to help you further. We offer a range of different customization techniques that allow you to create a unique and personalized tin that will help make your product stand out from the crowd.